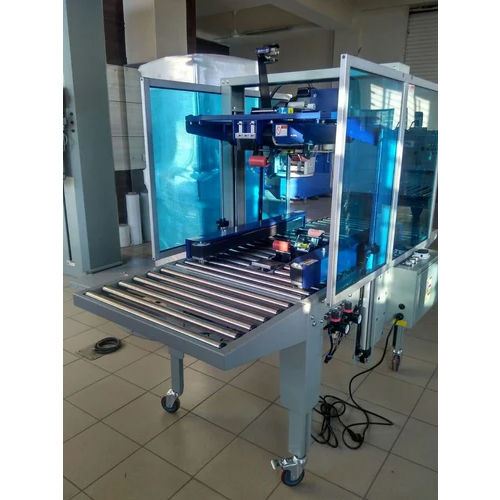

Cast Iron Strapping Machine

Cast Iron Strapping Machine Specification

- Type

- Strapping Machine

- Material

- Stainless Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- PLC Control

- Selection Mode

- Automatic

- Dimension (L*W*H)

- 780X777X540(WXHXD) Millimeter (mm)

- Color

- Blue

- Weight (kg)

- 52 Kilograms (kg)

- Warranty

- 1 Year

Cast Iron Strapping Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Cast Iron Strapping Machine

A Cast Iron Strapping Machine typically refers to a specific type of strapping machine that utilizes cast iron components in its construction. Cast iron is chosen for its durability, strength, and resistance to wear and tear, making it suitable for heavy-duty applications. These are commonly found in industries where robustness and reliability are critical, such as manufacturing, shipping, and warehousing. They are essential tools in industries requiring secure packaging and bundling of goods for transport and storage. Cast Iron Strapping Machine is designed for heavy-duty strapping applications where strength, durability, and reliability are paramount.

Efficient Strapping for Industrial Applications

Engineered from cast iron and stainless steel, this semi-automatic strapping machine delivers durability and consistent performance. Its design is suited for warehouses, factories, and logistic centers, where secure package binding is a priority. The machine's ease of use and sturdy build make it a dependable choice for both small and large-scale strapping operations.

Comprehensive Service and Warranty Support

As a solution provided by an Indian manufacturer, supplier, and service provider, this machine is backed by localized support and a 1-year warranty. Buyers benefit from accessible after-sales assistance, ensuring both quick installation and ongoing maintenance are handled seamlessly for uninterrupted operations.

FAQ's of Cast Iron Strapping Machine:

Q: How does the semi-automatic cast iron strapping machine operate?

A: This machine functions by allowing the operator to manually position the strap around the package, after which the machine tightens, seals, and cuts the strap automatically, streamlining the strapping process without the need for computerization.Q: What types of materials can this strapping machine handle?

A: While constructed with stainless steel for maximum longevity, the machine is suitable for securing packages with various strapping tapes, especially those used in industrial and commercial packaging applications.Q: When should I perform maintenance on this machine?

A: Routine maintenance, such as cleaning and checking moving parts, is recommended every few months or after prolonged, intensive use to ensure optimal performance and longevity.Q: Where can I access service and spare parts for this machine?

A: As an Indian manufacturer, supplier, and service provider, support and genuine spare parts are readily available across India, ensuring prompt assistance whenever needed.Q: What is the process for using the cast iron strapping machine?

A: Simply load the strapping material, position the package, insert the strap, and activate the semi-automatic process. The machine will automatically tighten and seal the strap efficiently.Q: What are the benefits of choosing a semi-automatic, non-computerized strapping machine?

A: This design offers user-friendly operation, reduced maintenance complexity, and increased mechanical reliability, making it ideal for users seeking dependable strapping without advanced programming knowledge.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Strapping Machine Category

Fully Automatic Random Tapeing And Strapping Machine

Price 750000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Computerized : No

Type : Strapping Machine

Warranty : 1 Year

Three Phase Fully Automatic Strapping Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Computerized : No

Type : Strapping Machine

Warranty : 1 Year

Automatic Vertical Side Seal Strapping Machine

Price 650000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Computerized : No

Type : Strapping Machine

Warranty : 1 Year

Automatic Box Strapping Machine For Corrugated Industry

Price 300000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Computerized : No

Type : Box Strapping

Warranty : 1 Year

Send Inquiry

Send Inquiry Send SMS

Send SMS