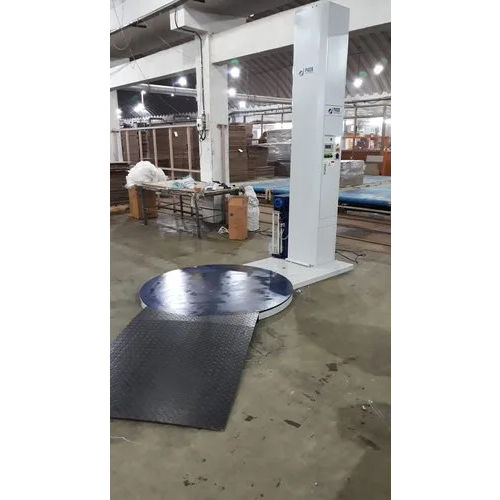

Pallet Wrapping With Top Pressing Machine

Pallet Wrapping With Top Pressing Machine Specification

- Product Type

- Pallet Wrapping With Top Pressing Machine

- Material

- Stainless Steel

- Capacity

- 20 Pallets/hr Pcs/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Voltage

- 230V Volt (v)

- Power

- 1000 Watt (w)

- Rotating Speed

- 0-15 RPM

- Weight (kg)

- 800 Kilograms (kg)

- Warranty

- 1 Year

Pallet Wrapping With Top Pressing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7-10 Days

- Main Domestic Market

- All India

About Pallet Wrapping With Top Pressing Machine

Reliable Pallet Stability

Featuring an integrated top pressing mechanism, this machine ensures each pallet is tightly secured to prevent shifting during storage or transportation. Its automatic grade further streamlines the wrapping process, enhancing productivity and load safety for various industries.

Stainless Steel Durability

Crafted using high-quality stainless steel, the machine is resistant to corrosion, offering longevity even in demanding environments. This robust material choice makes it suitable for warehouses, logistics centers, and factories dealing with heavy or sensitive goods.

FAQ's of Pallet Wrapping With Top Pressing Machine:

Q: How does the top pressing function enhance pallet wrapping efficiency?

A: The top pressing mechanism stabilizes the loads during the wrapping process, minimizing movement and ensuring that items remain securely in place. This feature reduces the risk of product shifting or damage, especially for unstable or irregularly shaped pallets.Q: What is the procedure for operating the automatic pallet wrapping machine?

A: Simply place the loaded pallet onto the machine's platform, initiate the automatic wrapping cycle, and the machine will begin wrapping while holding the load steady with its top presser. Operation is straightforward, requiring minimal manual intervention.Q: When should I use a pallet wrapping machine with a top press in my facility?

A: You should use this machine when handling loads that are unstable, lightweight, or have stacked items prone to displacement. It is ideal for facilities that ship fragile or loose products requiring added security during transit.Q: Where can this machine be effectively installed?

A: This automatic pallet wrapping machine can be efficiently installed in warehouses, manufacturing plants, logistics hubs, and distribution centers across India. Its stainless steel build makes it suitable for various industrial environments.Q: What warranty and after-sales support is provided with this equipment?

A: This machine is backed by a 1-year warranty, covering manufacturing defects and performance issues. As a manufacturer, service provider, supplier, and trader, comprehensive customer support and maintenance services are accessible throughout India.Q: How do I benefit from using a stainless steel, automatic pallet wrapper?

A: Utilizing this stainless steel automatic pallet wrapper enhances packaging consistency, speeds up palletization, and reduces manual labor. The material ensures long-term durability, while the automation boosts operational efficiency-delivering cost savings and improved workplace safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stretch Wrapping Machine Category

SS Coil Wrapping Machine

Price 550000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Coil Wrapping Machine

Automatic Grade : Automatic

Computerized : No

Material : Stainless Steel

JSW 01 TT 1500 Pallet Wrapping Machine With Turn Table

Price 285000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Pallet Wrapping Machine

Automatic Grade : Automatic

Computerized : No

Material : Stainless Steel

Coil Stretch Wrapping Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Coil Stretch Wrapping Machine

Automatic Grade : Automatic

Computerized : No

Material : Stainless Steel

JSW-1MB Box Stretch Wrapping Machine

Price 110000.0 INR / Number

Minimum Order Quantity : 1 Unit

Product Type : Box Stretch Wrapping

Automatic Grade : Automatic

Computerized : No

Material : Stainless Steel

Send Inquiry

Send Inquiry Send SMS

Send SMS